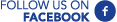

VGS Oil Separator

The Vertical Gravity Separator (VGS) is a flooded system in which the inlet and outlet columns form a U - tube configuration. The free oil and low density suspended solids are trapped on one side of the main body and the treated water flows out the other side.

Summary

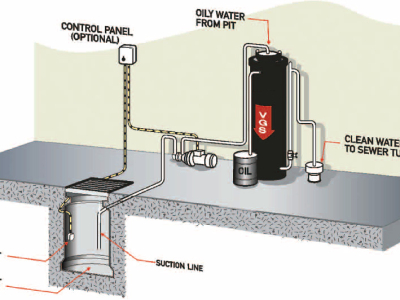

The main body of the unit ( VGS Oil Separators )contains a continuous truncated conical spiral pack (SPAK) which is manufactured from an oleophilic material.

Oily water is delivered into the bottom of the main body where it then flows upwards through the centre of the SPAK assembly. At the top of the main body free oil and low density suspended solids are held and eventually they flow out of the system for collection and suitable disposal.

The partially cleaned water is directed to the outside perimeter of the conical SPAK. It then follows a tortuous path cascading down and around the SPAK.

Here the lower density fluid (oil) is drawn up the incline of the oleophilic surface of the SPAK and back into the low pressure centre of the VGS, where it co-mingles with the incoming fluid and is redirected to the top of the main body.

A continuous convention current is created within the SPAK by the density and pressure variation down the fluid column and the upward flow of the cleaned water will enter the output leg of the separator and will flow up and out of the system, whilst the heavy solids will drop to the base of the vessel.

Applications

- Panel Beaters

- Auto Dismantlers

- Car Detailers

- Equipment Hire Companies

- Mechanical Workshops

- Raditor Repairs

- Service Stations/Fuel Depots

- Commercial Car Washes

- Loading Bays

- Engine Reconditioners